Sodium Metasilicate is an extender used to produce an economical, low density cement slurry. When cementing pipe in many types of wells, it usually is desirable to place a long column of cement in the annulus up into the last string of pipe, or back to the surface. The use of a “neat” cement slurry to fill this column is, in most cases, impractical due to the economics of pumping large quantities of neat cement when its high-strength properly is required only at the very bottom of the casing. So typically, an extended cement slurry is pumped to fill most of the annulus, followed by a higher strength, higher density, neat cement slurry to fill the area around the bottom of the pipe. This extended, lower density slurry also helps reduce the hydrostatic head of along slurry column and prevent lost circulation across pressure-sensitive zones.

Reduced Hydrostatic Pressure

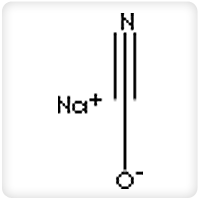

Small concentrations (1-4%) of Sodium Metasilicate allow the use of higher, more variable water-to-cement ratios which provide lower cost per cubic foot of slurry.

Reduced Hydrostatic Pressure

Higher water-to-solids (cement) extends slurry yield and lowers density. Slurries as light as 11.4 ppg (1,912 kg/m3) can be designed with Sodium Metasilicate.

Higher Strength

Strength normally is higher than for a comparable weight slurry using other extenders.

Reduces Free Water

Small concentrations (0.2 to 0.3%) reduce free water in normal and heavyweight slurries.

Specific gravity of 2.18 and is compatible with all API cements.

Furnishes higher compressive strength than other extenders of comparable slurry densities.

Provides low-density slurries that decrease the hydrostatic pressure on weak formations, thus reducing the chance of lost circulation.

Produces high yield, economical slurries.

Normally dry-blended in the cement.

Sodium Metasilicate is caustic and will cause chemical burns to the skin and eyes. Use all special procedures and equipment for personal protection.

Sodium Metasilicate slurries do not respond well to Calcium Chloride accelerators or CD-31 dispersant. It will respond to retarders but may require higher concentrations to achieve desired thickening time. Sodium Metasilicate should not be predissolved in the mixing water unless an activator, such as calcium chloride (1 to 1.5%), is dissolved first in the water.